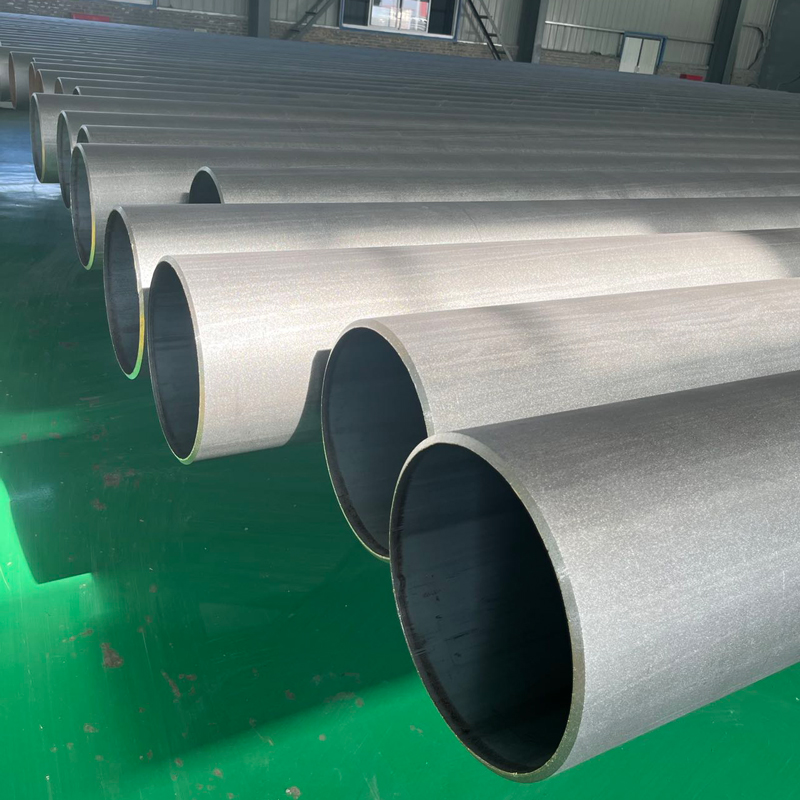

Fusion-Bonded Epoxy Txheej Awwa C213 Standard

Lub cev muaj zog ntawm epoxy hmoov cov ntaub ntawv

Lub ntiajteb txawj nqus tshwj xeeb ntawm 23 ℃: yam tsawg kawg nkaus 1.2 thiab siab tshaj 1.8

Sieve tsom xam: siab tshaj 2.0

Gel lub sij hawm ntawm 200 ℃: tsawg dua 120s

Abrasive moj tej tawg tu

Cov npoo ntawm cov hlau tsis muaj steel hlau yuav tsum tau ua kom huv si raws li SSPC-SP10 / NACE No. 2 tshwj tsis yog tus neeg yuav khoom tau teev tseg.Cov qauv blast thauj tog rau nkoj los yog qhov profile qhov tob yuav tsum yog 1.5 mil mus rau 4.0 mil (38 µm rau 102 µm) ntsuas raws li ASTM D4417.

Preheating

Cov yeeb nkab uas tau ntxuav lawm yuav tsum tau preheated ntawm qhov kub tsawg tshaj 260 ℃, qhov cua kub yuav tsum tsis txhob paug cov yeeb nkab nto.

Thickness

Cov hmoov txheej yuav tsum tau siv rau cov yeeb nkab preheated ntawm ib qho kev kho zoo-zaj duab xis thickness tsis tsawg dua 12 mils (305μm) ntawm sab nrauv lossis sab hauv.Qhov siab tshaj plaws thickness yuav tsum tsis txhob ntau tshaj ib tug nominal 16 mils (406μm) tshwj tsis yog tias pom zoo los ntawm cov chaw tsim tshuaj paus los yog teev los ntawm pruchaser.

Optional epoxy xeem kev ua tau zoo

Tus neeg yuav khoom tuaj yeem hais qhia qhov kev sim ntxiv los tsim kev ua haujlwm epoxy.Cov txheej txheem xeem hauv qab no, tag nrho cov uas yuav tsum tau ua nyob rau hauv cov yeeb nkab xeem rings, tej zaum yuav raug teev tseg:

1. Hla ntu porosity.

2. Interface porosity.

3. Kev ntsuas cua sov (DSC).

4. Kev ruaj khov (khoov tau).

5. Dej ntub dej.

6. Kev cuam tshuam.

7. Cathodic disbondment test.