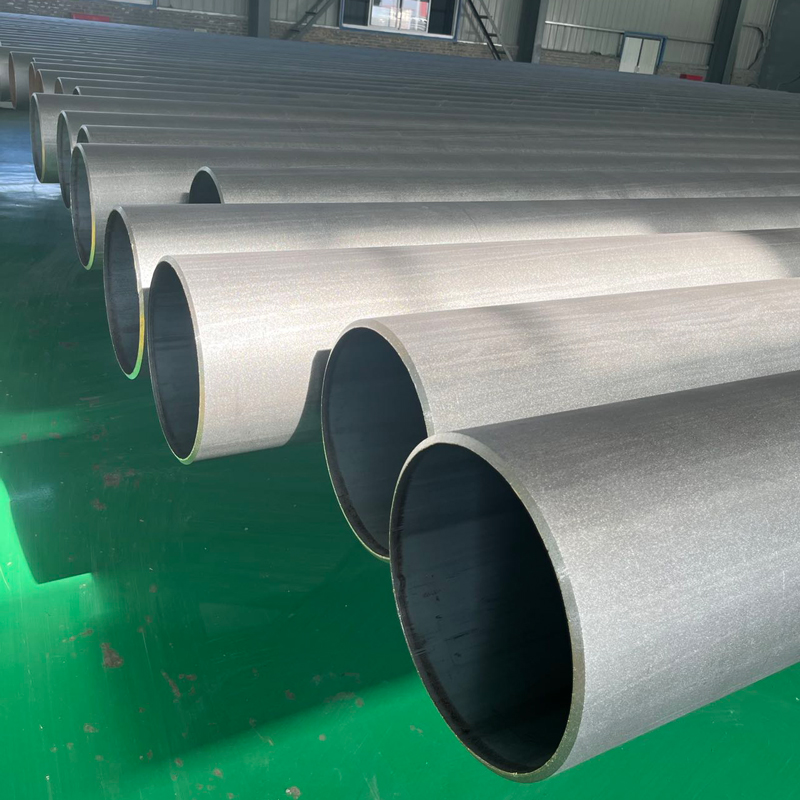

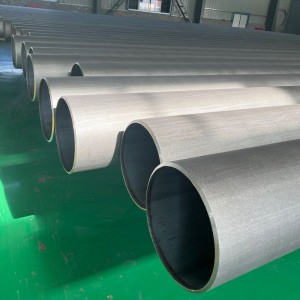

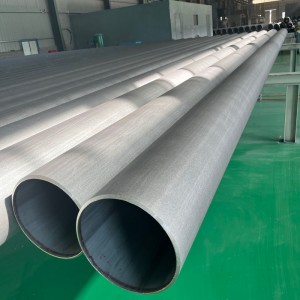

Fusion-Bonded Epoxy Coatings Awwa C213 Txheem

Cov khoom siv lub cev ntawm cov ntaub ntawv hmoov epoxy

Lub zog nqus tshwj xeeb ntawm 23 ℃: yam tsawg kawg nkaus 1.2 thiab siab tshaj plaws 1.8

Kev tshuaj xyuas lub sieve: siab tshaj plaws 2.0

Lub sijhawm gel ntawm 200 ℃: tsawg dua 120s

Kev ntxuav abrasive

Cov hlau uas tsis muaj qhov chaw yuav tsum tau ntxuav kom huv raws li SSPC-SP10/NACE No. 2 tshwj tsis yog tias tus neeg yuav khoom tau teev tseg lwm yam. Tus qauv txuas hlau lossis qhov tob ntawm qhov profile yuav tsum yog 1.5 mil txog 4.0 mil (38 µm txog 102 µm) ntsuas raws li ASTM D4417.

Ua kom sov ua ntej

Cov yeeb nkab uas tau ntxuav lawm yuav tsum tau preheated ntawm qhov kub tsawg dua 260 ℃, qhov chaw cua sov yuav tsum tsis txhob ua rau cov yeeb nkab puas tsuaj.

Qhov tuab

Cov hmoov txheej yuav tsum tau siv rau ntawm cov yeeb nkab uas tau ua ntej lawm ntawm qhov tuab ntawm cov yeeb yaj kiab kho kom zoo tsis pub tsawg dua 12 mils (305μm) ntawm sab nraud lossis sab hauv. Qhov tuab tshaj plaws yuav tsum tsis pub tshaj 16 mils (406μm) tshwj tsis yog tias tus neeg tsim khoom pom zoo lossis tus neeg yuav khoom tau teev tseg.

Kev ntsuam xyuas kev ua haujlwm epoxy xaiv tau

Tus neeg yuav khoom yuav teev cov kev sim ntxiv kom paub tseeb tias epoxy ua haujlwm tau zoo. Cov txheej txheem sim hauv qab no, uas yuav tsum tau ua rau ntawm cov nplhaib sim yeeb nkab ntau lawm, yuav teev tseg:

1. Qhov porosity hla ntu.

2. Qhov sib txuas ntawm qhov sib txuas.

3. Kev tshuaj xyuas cua sov (DSC).

4. Kev nyuaj siab tas mus li (kev khoov tau).

5. Dej ntub.

6. Kev cuam tshuam.

7. Kev sim tshuaj cathodic disbondment.